Articles > Lintel Products: Reviews & Comparisons

The upcoming section, "Introduction," serves the purpose of providing an overview of the topic to be discussed and establishing the context and significance of the content that follows. It will consist of key elements such as a brief overview of the topic, the main objectives, and any relevant background information that the reader should be aware of.

The introduction will set the stage for the rest of the content by providing a context for the topic and highlighting its significance. It will give the reader a glimpse into what they can expect to learn and why the topic is important or relevant. By including key background information, the introduction will ensure that all readers are on the same page and have the necessary context to understand the upcoming discussion.

In summary, the "Introduction" section will serve as a crucial starting point for the reader, laying the foundation for the content that follows and providing the necessary context and background information to understand the topic in its entirety.

Lintels are structural supports that are placed horizontally across the span of a window or door frame. They are essential for providing strength and load-bearing properties to the wall, as they help to distribute the weight of the structure above the opening. Without the support of lintels, the wall could potentially collapse under the weight of the building above.

There are different types of lintels available for various applications. For domestic use, standard steel or concrete lintels are commonly used. For industrial and commercial applications, precast concrete lintels or reinforced steel lintels may be used to support heavier loads. Another type of lintel commonly used in construction is the angle iron lintel, which is made from steel and is L-shaped to provide additional structural support.

In summary, lintels are critical for providing structural support and load-bearing capabilities to window and door openings. They come in various types to suit different load requirements for domestic, industrial, and commercial applications.

In construction, lintels are an essential structural element that plays a crucial role in supporting the load above an opening such as doors, windows, or archways. Lintels are important for distributing the weight of the structure and providing stability, ultimately ensuring the integrity and safety of the building. This article will delve into the significance of lintels in construction, highlighting their functions, types, and the materials used in their fabrication. From understanding the importance of proper lintel installation to recognizing their impact on a building's overall structural strength, this article will shed light on the indispensable role that lintels play in construction projects.

Lintels are horizontal structural elements used in building construction to support the load above openings such as doors and windows. There are several types of lintels used, each with its own characteristics, advantages, and disadvantages.

Brick lintels are made of bricks arranged in a rectangular shape. They are easy to install and provide a traditional look to the building. However, they are limited in span and may require additional support.

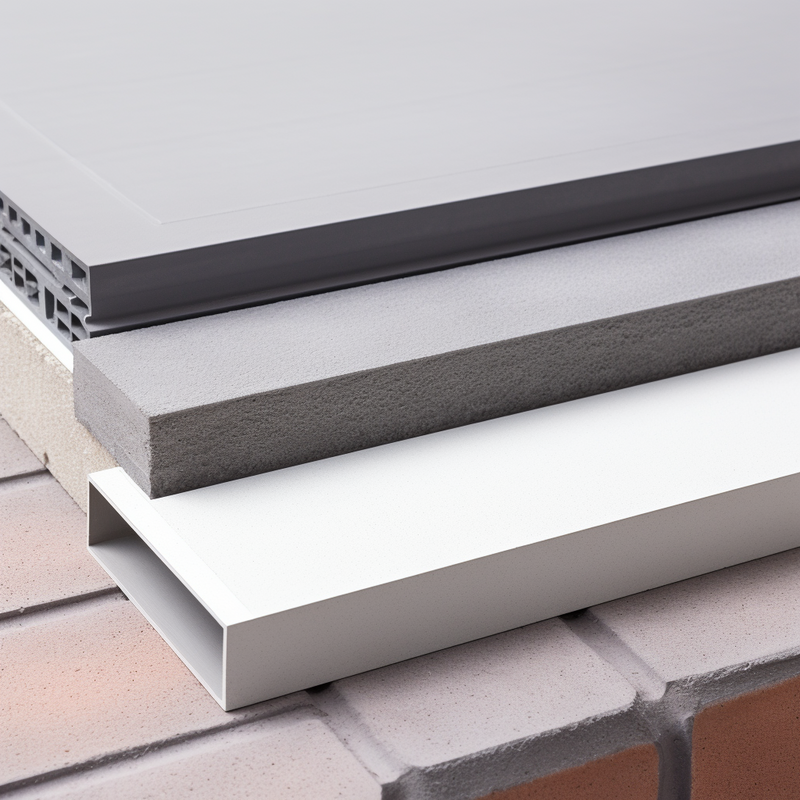

Precast lintels are manufactured off-site and then installed in the construction process. They are durable, have a uniform quality, and can be customized to fit specific requirements. However, they may be costly and heavy to handle.

Reinforced brick and concrete lintels are similar to their non-reinforced counterparts but have added steel reinforcement to increase their load-carrying capacity. They offer greater strength and durability but may be more expensive and labor-intensive to install.

Steel lintels are made of structural steel and are known for their high load-bearing capacity and versatility. They are lightweight, easy to handle, and can span long distances, but they may corrode if not properly protected.

Stone lintels are made of natural stone and offer a timeless, aesthetic appeal. They are durable and provide a rustic look to the building. However, they may be heavy and costly to source.

Each type of lintel has its own unique characteristics, advantages, and disadvantages, allowing builders to make informed choices based on their specific construction needs.

Lintels are essential structural components in building construction, providing support over openings such as doors and windows. There are three main types of lintels commonly used in construction: reinforced concrete lintels, steel lintels, and wooden lintels.

Reinforced concrete lintels are made from concrete reinforced with steel bars. They are durable, strong, and resistant to fire and corrosion. They are also versatile and can be easily shaped to fit different architectural designs. However, they are heavy and require careful handling and installation.

Steel lintels are made from structural steel and are known for their strength and stability. They are relatively lightweight, making them easier to handle and install. Steel lintels are also fire-resistant and can span longer distances compared to other materials. However, they are susceptible to corrosion and require protective coatings to prevent rusting.

Wooden lintels are the traditional choice for construction and are often used in smaller, residential buildings. They are lightweight, easy to work with, and provide a natural look. However, they are not as strong or durable as reinforced concrete or steel lintels and may require regular maintenance to prevent decay and insect damage.

When choosing a lintel type for construction, it is important to consider the specific requirements of the building, including the span, load-bearing capacity, and environmental conditions. Each type of lintel has its own characteristics, advantages, and considerations that should be carefully evaluated before installation.

Concrete lintels are essential structural components used to support and distribute the weight of the load above door and window openings. The installation process begins by placing the lintel on a level surface, ensuring that the correct bearing capacities for the specific lintel size and load are met. The lintel should be propped securely in place using steel props or timber supports.

Reinforced concrete lintels offer several advantages, including high strength, durability, and resistance to weathering and corrosion. When installing reinforced concrete lintels, it is important to consider factors such as proper positioning, ensuring adequate bearing capacity, and ensuring proper anchorage and support for the lintel.

Concrete lintels are available in a range of sizes and lengths to suit various door and window openings. Common sizes include 100mm x 65mm, 100mm x 75mm, and 150mm x 100mm. The lengths available are typically between 900mm to 2400mm. In Sydney and select areas in New South Wales, delivery options include direct delivery to the construction site or pickup from a local supplier.

Overall, the installation of concrete lintels requires careful planning and adherence to the specific bearing capacities and positioning requirements. Reinforced concrete lintels offer strength and durability, making them a popular choice for supporting door and window openings in construction projects.

Steel lintels are essential loadbearing supports used in construction and architecture to distribute the weight of heavy loads across wide openings. These steel beams are specifically designed to support masonry and brickwork above windows, doors, and other openings, ensuring structural integrity and stability.

One of the key advantages of steel lintels is their ability to bear heavy loads without deteriorating over time. This is due to their isotropic properties, meaning they have consistent mechanical and physical properties in all directions. This makes steel lintels highly durable and reliable, even under extreme environmental conditions. Their isotropic nature allows them to evenly distribute the weight of the structure they support, reducing the risk of deformation or failure.

Steel lintels play a crucial role in construction and architecture by providing a strong and stable framework for buildings. Their loadbearing capabilities and isotropic properties make them an ideal choice for supporting heavy loads across wide openings, ensuring the long-term structural integrity and durability of the overall construction.

Timber lintels have been commonly used in construction for many years, but they come with potential issues and disadvantages. One major concern is their structural weakness, especially when compared to alternative materials like steel or concrete. Timber lintels are also vulnerable to rot and woodworm infestation, which can compromise their integrity over time. Additionally, timber lintels are susceptible to dampness, which can further contribute to their deterioration. In the event of a fire, timber lintels pose a significant safety risk as they can quickly catch fire and fail, potentially leading to structural collapse.

If timber lintels are affected by rot, woodworm infestation, or dampness, it is essential to take immediate action. This may involve treating the affected areas to prevent further damage or, in severe cases, removing and replacing the lintels altogether. It is crucial to seek a specialist inspection to determine the best course of action, as different treatments may be required depending on the extent of the damage. Ignoring these issues can lead to potential safety hazards and costly repairs in the future.

In conclusion, while timber lintels have been widely used in construction, it is important to be aware of their potential drawbacks and to prioritize regular inspections and maintenance to ensure their longevity and safety.

Stone lintels have been a crucial architectural element in various cultures throughout history. These structures have been used to support the weight of walls or door openings, providing both function and aesthetic appeal to buildings. From the ancient civilizations of Mesopotamia to the classic architecture of Greece and Rome, stone lintels have played a significant role in the construction of impressive and enduring structures. In this article, we will explore the history, design, and significance of stone lintels, as well as their enduring presence in modern architectural practices.

Steel lintels are known for their superior structural strength and load-bearing capacity compared to other materials such as concrete and brick. Steel lintels have a higher load-bearing capability and are lighter in weight, making them a popular choice for construction projects. They are able to bear uneven loads, making them ideal for cavity wall applications where consistent load distribution is essential.

Determining the load-bearing weight of steel lintels involves considering the material makeup and length of the lintel. The load-bearing capacity is calculated based on the physical properties of the specific steel material used and the dimensions of the lintel. Factors such as the type of steel, its tensile and compressive strength, as well as the cross-sectional area of the lintel, all contribute to its load-bearing capacity.

In comparison, concrete lintels are heavier and may not have the same load-bearing capability as steel lintels. Brick lintels can also be used but are limited in their structural strength and load-bearing capacity. Ultimately, steel lintels offer superior strength and load-bearing capacity, making them a preferred choice for many construction applications.