Articles > Lintel Products: Reviews & Comparisons

Steel lintels are an essential component in construction, providing crucial support for openings such as doors and windows. Their durability and strength make them an indispensable choice for builders, ensuring the long-term stability and integrity of a structure.

Steel lintels are the preferred choice due to their practicality and numerous advantages over other options such as stone, wood, or brick lintels. Unlike wood, steel lintels do not rot or decay, and they have a higher load-bearing capacity. Compared to stone or brick lintels, steel lintels are lighter and easier to handle, making them more practical and cost-effective for construction projects.

Additionally, steel lintels are resistant to fire, moisture, and pests, further enhancing their durability and longevity in a building. Their ability to span wide openings without requiring additional support also makes them a popular choice for builders.

In summary, steel lintels play a crucial role in construction due to their durability, strength, and practicality. As the preferred choice for builders, steel lintels offer numerous advantages over other options, making them an essential component in ensuring the stability and longevity of a building.

Steel lintels are essential components in construction, providing support for door and window openings. There are several types of steel lintels available, each designed to meet specific structural and load-bearing requirements. Understanding the various types of steel lintels, their characteristics, and applications is crucial in choosing the right one for a construction project. From traditional angle lintels to cavity lintels and box lintels, each type offers unique advantages and benefits that cater to different building requirements. This article will explore the different types of steel lintels, their features, and their suitability for various construction applications.

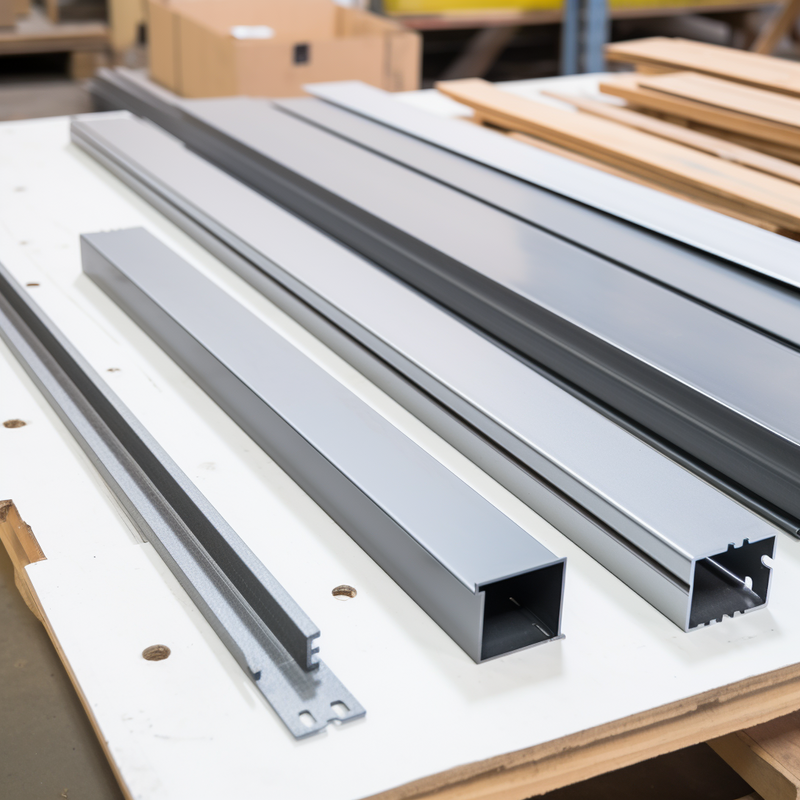

Box lintels are load-bearing structural components used in external solid wall constructions. They are typically made from materials such as steel, stone, concrete, aluminium, or wood. Box lintels are designed to support the weight of the masonry wall above door and window openings, distributing the load to the surrounding walls. They come in various sizes to accommodate different opening widths and heights, with typical dimensions ranging from 100mm to 300mm in depth and 100mm to 300mm in width.

Box lintels are suitable for large openings and heavy loads, providing greater load-bearing capacity compared to single leaf lintels. Single leaf lintels, on the other hand, are used for smaller openings with lighter loads. Box lintels are most appropriate when constructing external walls with wide and tall door and window openings, where the load-bearing requirements are high.

In conclusion, box lintels are crucial for supporting masonry walls above openings in external solid wall constructions. They come in different sizes and materials to accommodate various load-bearing needs, and are essential for ensuring the structural integrity and stability of the overall building.

Galvanized steel lintels are a popular choice in the construction industry due to their numerous benefits and features. These lintels are known for their exceptional durability, corrosion resistance, and long-term protection for buildings. The galvanization process involves coating the steel with a layer of zinc, which creates a barrier that effectively shields the steel from corrosion and rust. This ensures that the lintels maintain their structural integrity and strength over an extended period of time, making them a reliable choice for structural support in buildings.

The use of galvanized steel lintels is a key factor in ensuring the longevity of a structure. These lintels offer superior protection against environmental elements, such as moisture and harsh weather conditions, which can compromise the integrity of the building. Their robust construction and corrosion resistance make them the preferred choice over other lintel options in the construction market. Builders and architects value galvanized steel lintels for their strength, stability, and resistance to rust and deterioration, as these qualities contribute to the overall durability and reliability of the structure. In conclusion, galvanized steel lintels are an ideal choice for achieving long-term protection and structural integrity in any construction project.

Steel beams are a versatile and essential component in construction and engineering projects. They are available in various types, including I-beams, H-beams, and S-beams, each with its own unique features and applications. To enhance their longevity and corrosion resistance, steel beams can undergo treatments such as hot-dip galvanizing, where they are coated with a layer of zinc to protect against rust and corrosion. Chemical coating is another method used to ensure long-term durability and resilience.

In terms of sizes, steel beams come in a wide range, from 100mm x 75mm x 10mm to 100mm x 100mm x 8mm, catering to different load-bearing requirements and structural designs. The durability of steel beams is well-known, with high strength and resilience, as well as the advantage of not being reliant on composite action. This makes them suitable for various applications where superior strength and durability are essential.

Steel beams are an indispensable choice in construction and engineering due to their corrosion resistance, diverse sizes, and unmatched durability, making them a reliable and long-lasting option for various structural needs.

When choosing steel lintels for construction projects, there are several important considerations to keep in mind. From understanding the load-bearing requirements of the structure to factors such as cost, durability, and ease of installation, making the right choice is crucial to the success of the project. Additionally, the size, shape, and coating of the steel lintel should all be taken into account to ensure that it will perform effectively in the specific application. By carefully considering these factors, builders and architects can select the steel lintels that best meet the needs of their project, ultimately contributing to the overall strength and longevity of the structure.

Structural integrity is crucial in lintel design to ensure that the structural components can withstand the loads placed upon them, and to prevent cracking or spalling. It is important to consider the load, stress, and serviceability requirements to guarantee the safety and longevity of the structure. Consulting a certified structural engineer is necessary for the installation of any structural components to ensure that they are designed and installed according to industry standards and regulations. Vincent Buda can provide general advice on lintel design, but it is important to seek professional guidance from a certified engineer to ensure that all requirements are met. Their expertise will help to ensure that the lintel design meets all necessary load and stress requirements, and will help to prevent any potential structural issues in the future. Maintaining structural integrity through proper design and professional installation is essential for the safety and longevity of any structure.

The load-bearing capacity of lintels is influenced by several factors, including the floor loads, roof loads, and the weight of the wall they support. The floor load refers to the weight of the building's occupants and the furniture, while roof loads consider the weight of the structure, insulation, and potential snow accumulation. The weight of the wall also contributes to the overall load that the lintel must bear.

Uniform loads are distributed evenly across the lintel's span, while concentrated loads focus on specific points. Uniform loads can put consistent stress on the lintel, while concentrated loads can create higher localized pressure.

Safe Load Tables are essential in determining the total allowable load for structural components, including lintels. These tables provide information on the maximum loads that a particular lintel size and material can safely bear, taking into account factors such as the span and depth of the lintel. By referencing Safe Load Tables, builders and engineers can ensure that the lintel chosen can effectively support the expected loads, maintaining the structural integrity of the building.

The use of reinforced concrete and steel framing in the design of a structure greatly enhance its resistance to extreme loads such as wind, earthquakes, and heavy snow. Reinforced concrete is a composite material that combines the high compressive strength of concrete with the tensile strength of steel, resulting in a highly durable and resilient construction material. This makes it well-suited for withstanding the lateral forces of wind and seismic activity.

Steel framing is also crucial for structural stability, as it provides a high strength-to-weight ratio, allowing for a lighter and more flexible design that can better resist dynamic loads. Additionally, advanced building technologies, such as computer-aided design and construction (CADC), 3D modeling, and building information modeling (BIM), are utilized to optimize the structural integrity of the building. These technologies allow for more accurate simulations and analysis of structural behavior, resulting in a design that is better equipped to withstand extreme loads.

In conclusion, the combination of reinforced concrete, steel framing, and advanced building technologies in the design of a structure significantly enhances its resistance to extreme loads, ensuring its structural stability and safety.

Steel lintels are crucial components in the construction industry, providing structural support above openings such as doors and windows. Their popularity stems from a myriad of advantages that they offer, making them a go-to choice for many builders and architects. Some of these advantages include their durability, strength, resilience to various weather conditions, and their load-bearing capabilities. Additionally, steel lintels are known for their fire resistance and low maintenance requirements, making them a cost-effective and long-term solution for building projects. Their versatility and ease of installation further add to their appeal, making steel lintels an essential element in the construction of robust and reliable structures.

Lintels are an essential component in building construction, providing structural support over openings such as doors and windows. Different types of lintels exhibit strength and durability in relation to deflection and torsional limitations.

For example, concrete lintels are known for their strong compressive strength, making them suitable for carrying heavy loads without excessive deflection. Additionally, they have good resistance to torsional forces due to their rigid nature. Steel lintels, on the other hand, exhibit high tensile strength, making them effective in withstanding bending loads and minimizing deflection. They also have good resistance to torsional forces due to their inherent stiffness.

The impact of deflection and rotation on the strength and durability of lintels should not be underestimated. Excessive deflection can lead to cracking and compromise the structural integrity of the lintel, while torsional forces can cause twisting and buckling, leading to failure.

In conclusion, the choice of lintel material should align with the specific applied loads and twisting forces in order to ensure strength and durability. Proper consideration of deflection and torsional limitations is crucial for selecting the most suitable lintel for a given structural application.

Steel lintels come in a variety of sizes, widths, and lengths to cater to different construction needs. They are available in standard sizes ranging from 100mm to 300mm in width and lengths up to 6 meters, with varying strengths to support different loads. Custom-made designs are also an option, allowing for specific requirements to be met.

Different styles of lintels, such as corner, arched, and bay, can be customized to suit specific architectural and construction needs. This versatility in design and application makes steel lintels a popular choice in the construction industry.

Structural and stability advantages of using steel lintels include their rigidity and damp-proof features, ensuring long-term durability. Additionally, steel lintels are eco-friendly as they are fully recyclable materials, making them a sustainable choice for construction projects.

In conclusion, steel lintels offer a wide range of options in terms of size, width, length, and strength, as well as the ability to be custom-made to meet specific design and construction needs. Their structural advantages and eco-friendly nature make them a versatile and sustainable choice for various building projects.

When it comes to constructing buildings, the selection of lintels is a crucial decision that greatly impacts the overall structural integrity and aesthetics. There are several factors that must be considered when choosing the right type of lintel for a construction project. These factors include the type of load the lintel will bear, the material of the lintel, the dimensions needed, the level of insulation required, the depth of the opening, and the architectural design. Each of these factors influences the selection of lintels, and a careful consideration of each is essential to ensure the strength and longevity of the building. In this article, we will explore the key factors that influence lintel selection in construction projects.

Wall construction type can greatly influence the type and size of lintel required. For example, in a cavity wall construction, which consists of an inner and outer leaf separated by a cavity, the weight distribution between the two leaves needs to be considered when selecting a lintel. The inner and outer leaves may have different material compositions, which can impact the overall weight that the lintel needs to support.

In a solid wall construction, where there is no cavity and the entire wall is made from a single material such as brick or concrete, the lintel required will need to be able to support the full weight of the wall without the benefit of a cavity to redistribute the load.

When dealing with a block wall, the type of blocks used, such as concrete or clay blocks, and the manner in which they are laid will also impact lintel selection. The weight and load distribution in each type of wall construction will dictate the type and size of lintel required to ensure proper support and structural integrity.

When addressing roof load, several factors need to be considered. These include the span of the roof trusses, the type of load (whether it be uniform or concentrated), and consulting safe load tables for structural components. The span of the roof trusses will determine the distribution of the load across the structure, while the type of load will dictate the necessary strength and support required. It is important to understand the impact of roof trusses on the load, as they significantly influence the distribution of weight and the overall structural integrity of the roof. Before recommending a lintel, it is crucial to thoroughly comprehend how the roof trusses impact the load and ensure that the lintel can adequately support the added weight. Determining the loadbearing capacity of the roof is also paramount before designing for stresses, as it directly affects the safety and stability of the entire structure. By taking into account these considerations, a comprehensive and effective approach to addressing roof load can be implemented.